Catalog

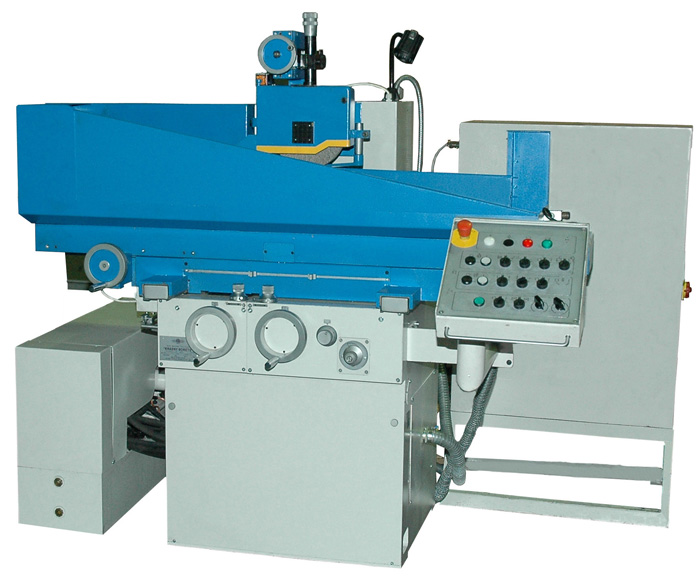

Surface grinding machines model 3D711VF11 are intended for high-precision machining of flat surfaces of various parts, using grinding wheel profiling parts mounting devices - profiled surfaces, slots, steps, and as well as grinding by wheel end face.

Surface grinding machine Osh-450 is intended for high-precision machining of flat surfaces of various parts, with help of wheel side and by end-face of grinding wheel, as well with use of devices for grinding wheel profiling and mounting of work pieces – profile surfaces, grooves, recesses.

The machines have been designed for high-precision grinding of flat surfaces of various articles, and when the grinding wheel periphery profiling and installation of attachments are used – for machining of profile surfaces, slots, shoulders, and also grinding with wheel face.

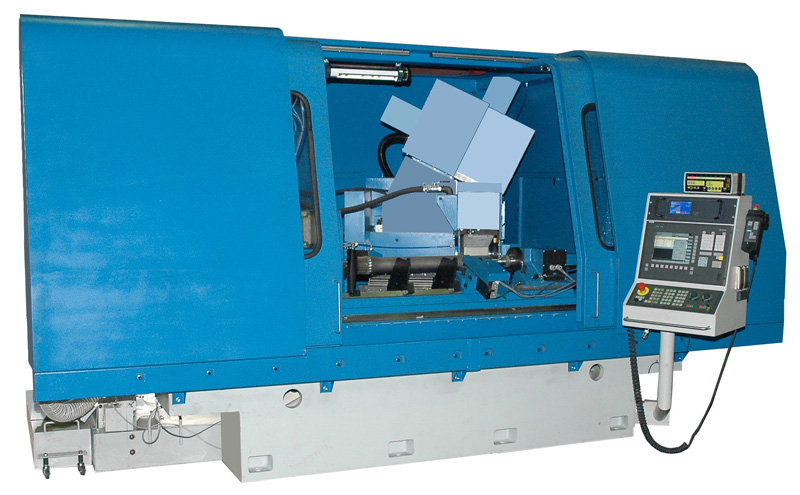

The semiautomatic grinding machine is intended for grinding outer cylindrical surfaces and slots in multistep “body of revolution” typework pieces, as well as outer surfaces of cog-type work pieces.

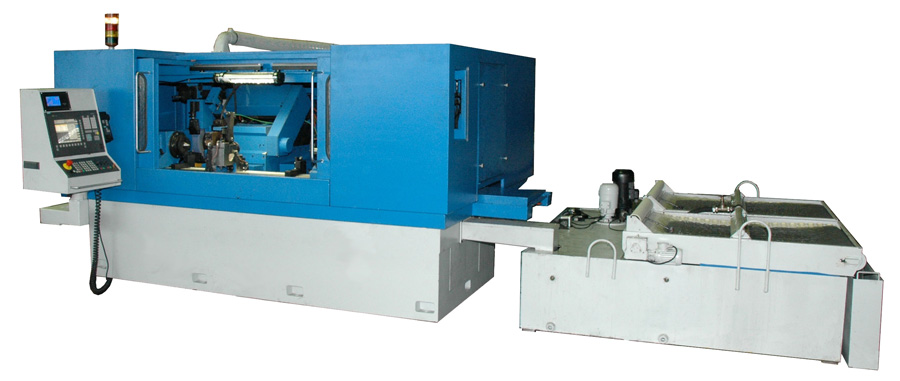

Flat profile grinding semiautomatic CNC machineis intended for final grinding of flat surfaces and profiles, representing combination of sections, straight lines, arcs, circles and other pre-defined curves in Cartesian coordinate system.

Grinding wheel profiling is carried out with help of rolling diamond rolls, mounted at the table by reciprocal movement of grinding head and carriage by Yand Z coordinates.

Machines are designed for machining of flat surfaces of articles from ferrous and non-ferrous metals installed and fixed on round table faceplate mirror or on electromagnetic chuck fixed on a faceplate by method of grinding.

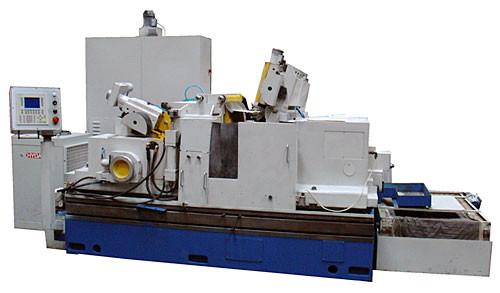

The machine is designed for outward grinding of diameters and adjoining to them faces by abrasive or el’bor borazon material wheels.

Machine is designed for machining of flat surfaces of different articles installed and fixed on faceplate mirror of round rotary inclinable table or on magnetic chuck fixed on faceplate.

Machines are designed for high accuracy machining flat as well as profile surfaces, representing combinations of segments, straight lines, arcs, circles and other precisely set curves in right-angled coordinate system. Profiling of grinding wheel is realized by means of rotating diamond roller installed on the table by grinding wheel head travel over coordinates Y and Z by means of CNC.

The machines have been designed for high-precision grinding of flat surfaces of various articles, and when the grinding wheel periphery profiling and installation of attachments are used – for machining of profile surfaces, slots, shoulders, and also grinding with wheel face.

Semiautomatic machine with CNC OSH-600F3 is designed for rough and finish grinding of cams of camshafts with convex profile and also for machining of parts of analogous type with fixation in centres or in a chuck and for grinding of outside cylinder and cone surfaces of smooth and stepped articles.

Semiautomatic machine is designed for high precision grinding of outward and inward cylindrical surfaces and also faces in multi–step parts - a kind of rotation body. Sphere of use of semiautomatic machine is enterprises with large-scale and mass production.

The machines have been designed for high-precision grinding of flat surfaces of various articles, and when the grinding wheel periphery profiling and installation of attachments are used – for machining of profile surfaces, slots, shoulders, and also grinding with wheel face.

The semiautomatic machines are intended for grinding of smooth, stepped, conical and shaped surfaces of bodies-of-rotation type by method of plunge-cut or through-feed grinding. Workpieces of cast iron, steel, non-ferrous metals and their...